what is it

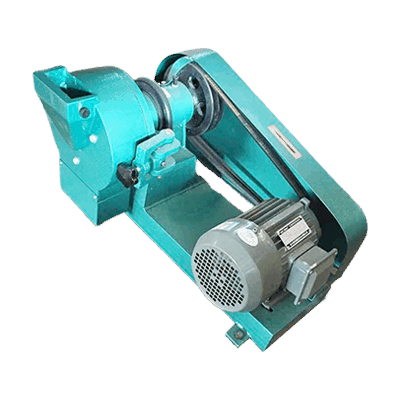

Laboratory Disc Pulverizer

Capacity: 6-100kg/hr

Application:It is widely used in pulverizing materials in geology, metallurgy, mining research, pharmaceuticals, environmental science and laboratory fields.

Description

Laboratory disc pulverizer is also called laboratory disc mill. Its main function is to grind various materials into fine powder for subsequent experiments, chemical analysis or other tests. Our laboratory shredders are equipped with powerful rotating crushing discs with toothed structures on the bottom and walls of the crushing chamber for enhanced sample crushing. In addition, this laboratory pulverizer allows adjustment of the grinding settings, ensuring optimal particle size control for specific research requirements. Easy to clean and maintain, it is perfectly suitable for comminution and pretreatment of samples such as ores, rocks, coal, minerals, etc., in research laboratories, educational institutions and industrial environments.

Advantages

Efficient and fast

Its high-speed rotation and sharp grinding teeth can quickly reduce large samples into fine powder in a few minutes.

Adjustable particle size

This lab disc pulverizer can precisely control particle size and distribution with high-speed rotating discs and adjustable grinding plates/discs.

Versatile Design

Suitable for various materials, such as ores, minerals, rocks, soil, and even cement clinker.

Easy to use

Grinding discs or discs can be easily removed, cleaned and replaced without much expertise and maintenance.

Repeatability

The lab disc crusher can repeatedly perform the same crushing process by setting the same parameters to ensure the reliability and repeatability of the experimental results.

Keep samples pure

Lab disc pulverizers are usually operated in a closed environment, which helps to avoid external contamination of samples and maintain the purity of samples.

Principle

The laboratory disc pulverizer mainly comprises a motor, a transmission device, a crushing disc and a crushing chamber. Put the sample to be crushed into the crushing chamber, and then start the motor. The rotation of the motor is transmitted to the crushing disc through the transmission device so that the crushing disc starts to rotate at high speed. The sample is put on the rotating crushing disc, sheared, crushed, impacted by the tooth-like structure, and gradually broken into smaller particles. The fineness of sample crushing can be controlled by adjusting the crusher’s working time, the crushing disc’s rotating speed and the crushing chamber’s structure. Once the sample reaches the desired fineness, the motor is turned off, and the crushed sample is taken out for subsequent experiments or analysis.

Specification

| Model | Φ150 | Φ175 | Φ250 |

| Feeding Size (mm) | ≤2 | ≤3 | ≤6 |

| Discharging Size (mesh) | 80 | 50 | |

| Main Shaft Speed (rpm) | 1050 | 1050 | 800 |

| Throughput (kg/h) | 6-20 | 10-35 | 20-100 |

| Dimensions (mm) | 550×490×365 | 550×490×365 | 770×510×500 |

| Weight (kg) | 90 | 130 | 180 |

| Power (kW) | 1.1 | 1.5 | 2.2 |