what is it

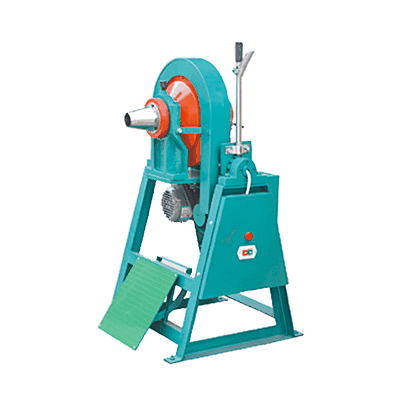

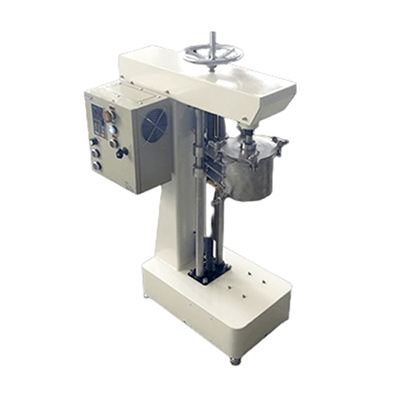

Bond Work Index Test Ball Mill

Popular Models: Our FC Bond mill is designed to have internal mill dimensions that deviate no more than 0.10″ from the specified 12″ x 12″ by Mr. Bond.

Motor Power: 0.75-1.1kw

Application: It is widely used in mining, metallurgy, building materials, chemical industry and other fields, especially for grinding performance testing and ore beneficiation process design.

Description

Bond Work Index Test Ball Mill is an experimental equipment used to determine the hardness and grinding performance of ore. Help in choosing the right grinding equipment for your ore.

Bond Work Index (BWI for short) is an index used to measure the hardness of ore. It is calculated by conducting a grinding test on ore samples under certain conditions and measuring the energy required. The higher the BWI value, the greater the hardness of the ore and the worse the grinding performance.

Advantages

Simple structure

the equipment is composed of drum, motor, reducer, transmission shaft, etc., with simple structure and easy operation and maintenance.

Easy to operate

By controlling the start-stop and speed of the equipment, the time of the grinding process and the amount of grinding media added can be adjusted.

Accurate and reliable

Through the sophisticated sensor and control system of the equipment, accurate experimental data can be obtained to ensure the reliability of the results.

Principle

Bond Work Index Test Ball Mill usually consists of a rotating cylinder and a set of steel balls. The ore sample is placed in the cylinder, and steel balls are added to it. By rotating the cylinder, the steel balls collide and rub against the ore sample, thereby realizing the grinding process.

Over a certain period of time, the wear characteristics of the material are evaluated by measuring the change in the fineness of the sample. According to the obtained data, the Bond Work Index value of the ore can be calculated. This value can be used to evaluate the hardness of the ore, and as a basis for the design and optimization of the grinding process.

Specification

| Item | Unit | XMGQΦ305×305 | XMGQΦ305×610 |

| Drum Size | mm | Φ305×305 | Φ305×610 |

| Drum Speed | r/min | 70±0.5 | 46±0.5 |

| Motor Power | kw | 0.75 | 1.1 |

| Ball Added | kg | 20.568 | 33.38 |

| Feed Size | mm | <3.2 | <12.7 |

| Feed Volume | cm³ | 700 | 1250 |

| Dimensions | mm | 1500×650×1100 | 930×610×1185 |

| Weight | kg | 330 | 400 |