what is it

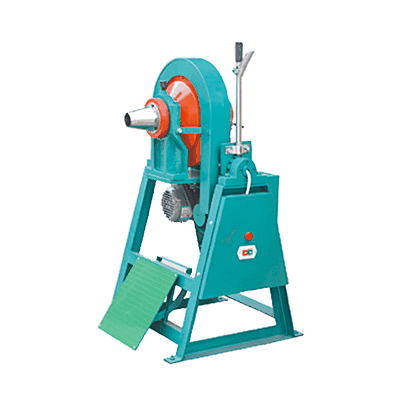

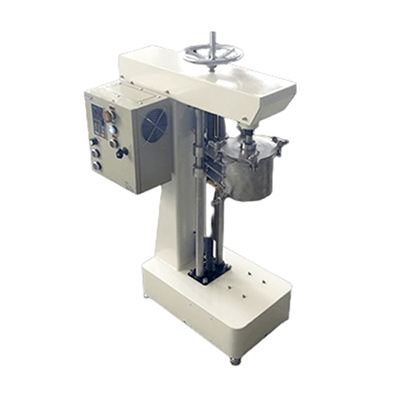

Laboratory Ceramic Ball Mil

Capacity: 0.25-5kg/h

Application: Lab Ceramic Ball Mill is widely used in laboratories, scientific research institutions and universities for grinding and mixing ores, chemical materials, medicines, food and other materials.

Description

Lab Ceramic Ball Mill is used for grinding and mixing various materials. It mainly consists of a rotating ceramic grinding Jar and ceramic balls, which can carry out efficient grinding and mixing process in the jar.

Lab Ceramic Ball Mill’s grinding jars and grinding balls are made of ceramics, which have good wear resistance and corrosion resistance, adapt to a wider range of materials, and grind finely and evenly.

Advantages

Wear-resistant and corrosion-resistant materials

Made of ceramic materials, with high wear resistance and corrosion resistance, it can adapt to more materials.

Good grinding effect

Ceramic grinding balls provide a more uniform and fine grinding effect. Suitable for demanding experiments and research needs.

Precise control

Equipped with a digital control system, it can precisely control the grinding time, speed and rotation direction to meet different grinding requirements.

Principle

The Lab Ceramic Ball Mill operates by driving the grinding jar to rotate through an electric motor. The ceramic balls and the grinding material inside the jar are driven to rotate and collide with each other. During this process, the grinding material is gradually crushed and finely ground.

Specification

| Model | XMCQ-φ180×200 | XMCQ-φ280×290 |

| Cylinder Size | 5.1L | 17.9L |

| Fee Size | ≤2mm | ≤2mm |

| Discharge Size | ≤0.074mm | ≤0.074mm |

| Capacity | 250g/h | 3-5Kg/h |

| Motor Power | 0.55KW | 0.75KW |

| Dimensions | 1052×613×1160mm | 1052×570×1246mm |

| Weight | 150Kg | 180Kg |