what is it

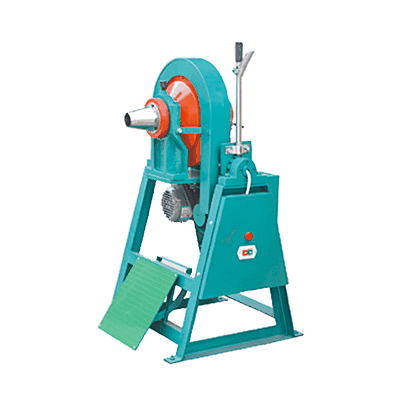

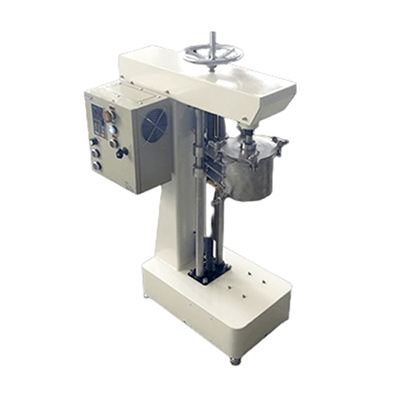

Pilot Ball-Rod Mill

Popular Models: The 911MPEPPGR426 can grind 6mm ore to 75 microns, and can grind 300 kilograms to 3.5 tons of materials every day.

Capacity: 150kg/hr

Application: Pilot Ball-Rod Mill is suitable for small-scale experiments and production. It can conduct batch grinding test to evaluate the grinding performance of ore and determine the optimal grinding process parameters. Often used in laboratories、universities/research institutions.

Description

Pilot Ball-Rod Mill is a wet grinding equipment. It is mainly composed of feeding part, grinding part, grading part and conveying part. The equipment is small in size and simple in structure, and is suitable for determining the grindability index of ore in the laboratory.

Due to the spiral classifier in the equipment, a closed-loop grinding device can be formed.

Advantages

Simple structure, convenient installation and use.

Grinding closed circuit design improves the grinding effect.

The four motors are independently driven, and the equipment has high flexibility in use.

Principle

1. Feeding: The disc feeder uniformly and continuously feeds the material to the volute feeder, which delivers the material with water to the grinding cylinder. The feeding amount is adjustable.

2. Grinding: The grinding process is completed by a Φ200×240 cylindrical drum, which is lined with corrugated manganese steel. The drum is driven by an electric motor.

3. Discharging: The ground material is discharged from the overflow end. There is a hose on the discharge chute to allow water to flow out and adjust the water quantity. In closed-circuit grinding, the material flows into the spiral classifier. In open-circuit powder grinding, the discharge chute is removed and a collecting chute is installed.

4. Conveying: The conveying section transports the coarse particles in the spiral classifier through the volute feeder to the grinding cylinder, thereby achieving continuous powder grinding.

Specification

| 1. 35L Swing Feeder | 2. Φ90*600 Spiral Conveyor | ||||

| Bin Volume (L) | 35 | Diameter (mm) | Φ90 | ||

| Vibratory Frequency (RPM) | 19 | Length(mm) | 600 | ||

| Feed Capacity (kg/h) | 6-200 | Spiral speed (RPM) | 38 | ||

| Motor (Kw) | 0.12 | Motor (Kw) | 0.12 | ||

| Motor Speed (RPM) | 1400 | Motor Speed (RPM) | 1400 | ||

| 3. Φ420*600 Grinding Mill | 4. Φ150*1400 Spiral Classifier | ||||

| Mill Shell Size (mm) | Φ420*600 | Diameter (mm) | Φ150 | ||

| Mill Speed (RPM) | 57 | Length (mm) | 1400 | ||

| Mill Volume (L) | 80 | Overflow End Width (mm) | 240 | ||

| Capacity(Kg/h) | 150 | Tilt Adjustment Range (°) | 15°30’,22° | ||

| 100L-6 | Spiral Speed (RPM) | 18,23,30 | |||

| Motor Model | |||||

| Rod Charge (kg) | 50 (Φ25) | Motor | Model | YS7124-4 | 100L-6 |

| 45 (Φ35-Φ40) | Power (Kw) | 0.55 | 1.5 | ||

| 60 (Φ30) | Speed(RPM) | 1400 | 920 | ||

| Feed Size (mm) | ≤6 | Feed Size (mm) | ≤6 | ||

| Discharge Size (mm) | ≤0.074 | Discharge Size (mm) | ≤0.074 | ||

| Feed Volume (Kg/h) | 700 | Feed Volume (cm³) | 700 | ||

| Motor (Kw) | 2.2 | Weight (Kg) | 800 | ||

| Motor Speed (RPM) | 920 | Maximum Return Sand Ratio (%) | 300 | ||