The laboratory spiral chute is smaller than ordinary spiral chutes. It is suitable for indoor mineral processing experiments. This equipment is a commonly used gravity beneficiation equipment for universities, research institutes, and beneficiation plants to conduct mineral ore selectivity research and experiments. Its beneficiation effect is not much different from that of large-sized spiral chutes. The laboratory spiral chute is suitable for sorting particle size from 0.2 to 0.02 millimeters iron, ilmenite, chromite, pyrite, tungsten, tin, tantalum niobium, placer gold ore and other non-ferrous metals, rare metals, and non-metallic minerals with specific gravity differences. The spiral chute is widely used in various combined processes such as weak and strong magnetic, flotation, and gravity separation. It plays a role in supplementing, assisting, improving, and enhancing processes or operations.

Advantages

The laboratory spiral chute has the advantages of a smooth separation process, a relatively large range of allowable changes in feed density, a high enrichment ratio, a high recycling rate, a small footprint, low water consumption, simple structure, no need for power, strong processing capacity, easy installation, convenient operation, low investment, and quick results. It often works with other experimental equipment like magnetic separators, flotation machines, shaking tables, and gold centrifuges for coarse selection to recover and separate minerals.

- Extremely high efficiency, high recovery rate, and precise screening of ores

- No power required

- Lightweight, rust-resistant, durable, wear-resistant, and corrosion-resistant, low cost, long service life

Laboratory Spiral Chute

1. Structure

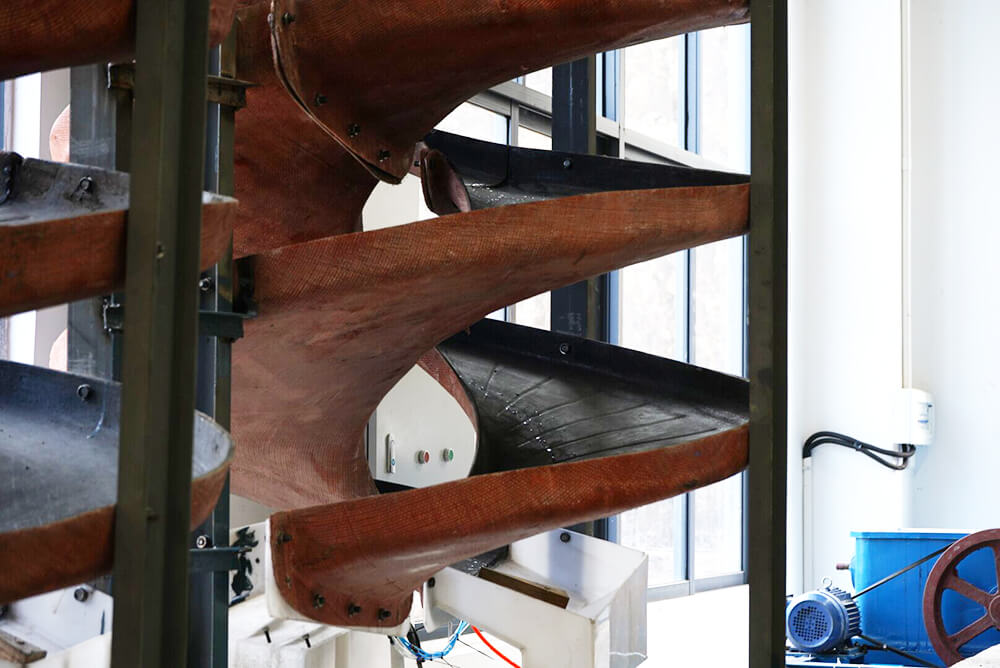

The spiral chute includes six parts: ore homogenizer, ore feeding trough, spiral trough, product interception trough, ore hopper, and trough support.

- The spiral groove composed of spiral blades is the main component. Spiral plates are made of fiberglass-reinforced plastic (FRP) and connected by bolts. Fiberglass spiral plates are lightweight yet sturdy. Its selective working surface has a wear-resistant layer, which is durable and long-lasting.

- The tank has a multi-tube ore homogenizer, which evenly divides the ore and is easy to control. The evenly distributed slurry slowly enters the spiral groove surface by feeding the ore.

- The tail end of the spiral groove has a valve block-type product interception groove, which divides the sorted ore flow into several products according to grade. Adjust the position of the valve block to change the cutting width of each product. The ore hopper is a concentric circular cylinder that collects and exports multiple ore streams.

2. Separating principle

- The spiral chute separator belongs to the inclined surface flow sorting process. Mineral mortar is applied to inclined grooves or slopes, and under the force of water, the mineral particles become loose and layered. The lighter minerals in the upper layer quickly flow out of the groove, while the heavier minerals in the lower layer stay inside the groove or flow out at a low speed from the lower part. After differentiation, we will obtain the selected ore and tailings.

- The spiral chute is a mining and beneficiation machine, especially ideal for sand mining on beaches, riverbanks, sandy shores, and riverbeds. The product has the characteristics of correct construction, simple installation, small land occupation, easy operation, stable ore selection, screening of ore, large production volume, high efficiency, high ore concentration ratio, high recovery and utilization rate, and reliable operation. It has advantages like lightweight, moisture-resistant, rust prevention, and wear-resistant, and highly applicable to fluctuations in feed quantity or density, particle size, and grade.

3. Operation Steps

- Raise the fiberglass chute, align it with the vertical line, and stabilize it in a suitable position with an iron frame or wood. Use a sand pump to deliver the ore sand to the top two inlet points of the spiral, increase water, and adjust the density of the ore slurry.

- The mineral slurry naturally spirals from top to bottom, generating an inertial centrifugal force in the inclined flow velocity during rotation. With the difference in gravity, particle size, and shape of the sand and ore, the gravity and centrifugal force of the spiral flow separate the ore and sand.

- The concentrate enters the hopper and connects to the sand tank through a pipeline, and the tail sand enters the tail sand hopper and connects to the sand tank through a pipeline. Then, a mortar pump discharges it, completing the entire beneficiation process.

4. Application Fields

Spiral chutes are suitable for separating fine-grained iron ores, titanium iron ores, chromium iron ores, sulfur iron ores, sand tin, tantalum niobium ores, gold ores, coal, monazite, rutile, zircon, rare earth, and other metallic and non-ferrous metal minerals with sufficient density and specific gravity differences.

5. Custom Services

- The numbers of chute can be customized according to specific customer requirements.

- The essential factor affecting the processing capacity of the chute is the specific number of installation heads for each chute. The number of chute installation heads is not changeable, but the number of blades at each chute head is adjustable according to customer requirements.

- The flatness requirements for the placement of spiral chutes are strict. After installation, it is necessary to check whether the support columns of the chute are vertical. If there are any deviations, use a steel pad for vertical correction. The installation height of the chute must installed according to the actual situation on site to facilitate the collection of concentrate, tailings, and intermediate ore.

JXSC lab mineral processing equipment manufacturer has more than 38 years of experience in mining processing. We provide various lab mining equipment including gravity-separating equipment for processing minerals such as gold, tin, tungsten, lead, zinc, tantalum, niobium, iron, manganese, silver, titanium-iron, etc. Lab machines include laboratory jaw crusher, hammer crusher, roller crusher, grinding equipment, lab gravity separator, screening, washing equipment, etc. Welcome to consult!