The mineral processing shaking table is a common equipment for separating fine-grained ores. It consists of three main parts: bed surface, frame, and transmission mechanism. In addition, there are flushing tanks, feeding tanks, machine bases, etc. The entire bed surface is supported or suspended by a frame, with a slope adjustment device. The shaking table is the most common gravity separation equipment to separate materials based on weight differences, often in gold, tungsten, and other heavy mineral recovery. Here we will introduce the 4 common types of mineral processing shaking table for mining beneficiation.

Conventional Shaking Table

A conventional mining shaking table is a gravity separation machine for mineral processing to separate fine materials based on their density and particle size. It operates on the principle of gravity and can effectively concentrate minerals such as gold, silver, tungsten, and other heavy minerals.

Applications

- Gold Recovery: One of the primary applications of conventional shaking tables is to recover gold from alluvial deposits and processed ore.

- Heavy mineral concentration: This machine separates heavy metals from lighter materials in various mining operations.

- Laboratory Testing: Often employed in laboratories to test the separation efficiency of different ore types.

Advantages

- High Recovery Rates: Conventional shaking tables are famous for their high recovery rates of valuable minerals.

- Simplicity and Effectiveness: The design and operation of shaking tables are relatively simple compare to other separation techniques.

- Environmentally Friendly: They do not require chemicals for mineral separation, making them a more environmentally friendly option.

Conclusion

Conventional mining shaking tables are crucial tools in mineral processing, particularly for fine-size materials. Their efficient separation capabilities make them integral mining operations in recovering valuable minerals. Their simplicity, effectiveness, and ability to operate without harmful chemicals contribute to their widespread use in the industry.

Gemini Shaking Table

The Gemini shaking table is for separating mineral raw materials with significant density differences between minerals and gangue, such as tungsten, tin ore, and gold ore. Gravity separation is the essential method for coal separation. The grooves on the bed surface are designed to optimize the enrichment of gold particles. This machine can process low-grade concentrates while achieving high gold recovery rates and grades.

Advantage

- Reasonable price.

- Wide particle size range of materials, with coarse ones up to several hundred millimeters and fine ones up to 0.02mm.

- Low environmental pollution and easy dehydration of products. However, for ores smaller than 0.1mm and coal smaller than 0.5mm, this machine’s beneficiation efficiency and equipment processing capacity are relatively low.

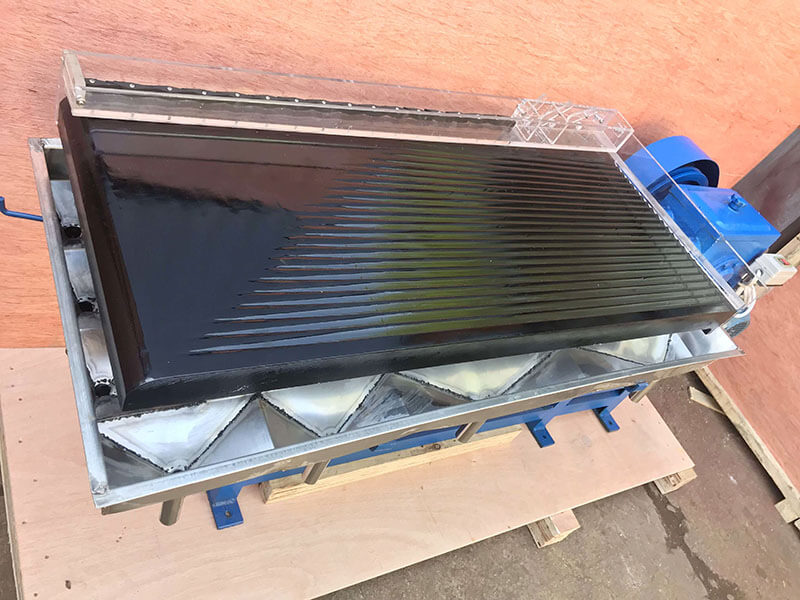

Multi-deck Shaking Table

The feature of multiple layers or decks increase separation efficiency, making them suitable for processing larger quantities of material.

Introduction

The multi-layer shaking table is a shaking table with two or more layers. There are stacked double-layer, overlapping double-layer, double triple-layer shaking tables, etc. The shaking table can process materials ranging from medium to fine particles with high separation accuracy, and the bed surface shape and movement are relatively simple. However, its production capacity per unit area is low, so multi-layer working surfaces are necessary. It is suitable for separating tungsten, tin, tantalum, niobium, gold, and other rare and precious metal ores. This machine can be applied for different tasks like rough selection to distinguish between coarse sand (2-0.5mm) and fine sand(0.5-0.074mm), mineral mud (-0.074) and other different particle sizes. It is suitable for separating iron, manganese ore, coal, tungsten and tin, etc.

The function of a multi-layer shaking table

- This machine is suitable for separating mineral sand or fine ore, and metal ore dry-sorting for coal preparation. Use with minimal changes in feed properties and amounts, as well as during rough selection operations.

- The headboard and bed surface are suspended by steel wire ropes on metal brackets or prefabricated hooks of the building. It not only eliminates the need for bulky foundations but also eliminates vibration and impact on the building.

- The inertial force at the head of the bed is transmitted to the shaker frame through a ball and socket connector, linking the bed surface with the head of the bed. Install a self-locking worm gear slope adjustment device on the steel frame, and change the slope of each layer of bed surface together during slope adjustment.

- Feed the slurry and water into the ore feed tank and water feed tank of each bed surface. The multi-layered overlap of the bed surface increases the processing capacity and saves the floor area.

Laboratory Shaking Table

The laboratory shaking table is one of the equipment for conducting ore separation research, experiments, and gravity beneficiation in small beneficiation plants. It is suitable for separating fine and fine rare metals, ferrous metals, non-ferrous metals, precious metals, and other ores and coal.

Features

- The small-scale mineral processing shaking table refers to the LY-type small mineral processing shaking table. It is made of fiberglass. Now we have a stainless steel and aluminum alloy experimental small shaking table with better beneficiation effects.

- LY shaker is one of the machines for laboratory research on ore separation, experiments, and small-scale beneficiation plants for gravity beneficiation. It is suitable for separating fine and fine rare metals, ferrous metals, non-ferrous metals, precious metals, and other ores and coal.

- This machine is a standalone beneficiation machine. It also can work with other beneficiation equipment such as a jig separator, spiral classifier, centrifugal concentrator machine, etc.

Advantage

- The selection process is stable and easy to control.

- Large allowable range of variation for ore concentration, with a high enrichment ratio and recovery rate.

- Small footprint, low water consumption, simple structure, no need for power, and large processing capacity.

- The advantages include easy installation, convenient operation, small investment, and quick returns.

JXSC lab mineral processing equipment manufacturer has more than 38 years of experience in mining processing. We provide various lab mining equipment including gravity-separating equipment for processing minerals such as gold, tin, tungsten, lead, zinc, tantalum, niobium, iron, manganese, silver, titanium-iron, etc. Lab machines include laboratory jaw crusher, hammer crusher, roller crusher, grinding equipment, lab gravity separator, screening, washing equipment, etc. Welcome to consult!