The tungsten-tin beneficiation process involves several complex steps and aims at extracting these precious metals from the raw ore. These metals have high economic value due to their widespread applications in modern industrial technology, especially in electronics, aerospace, medical equipment, and chemical industries. The mineral processing process usually involves various mechanical equipment, such as shaftless trommel screens, jig separators, vibration chutes, three-disc magnetic separators, and high-voltage electric separators, each of which plays a key role.

Tungsten-Tin Beneficiation Process

1. Primary screening and grading

The beneficiation process begins with the crushing and screening of the raw ore. After initial crushing, it usually uses the Trommel screen for grading and classifying. The shaftless trommel screen is suitable for raw ore containing large block materials. Its design has no central axis, which can reduce the possibility of material jamming and ensure the continuity and efficiency of screening.

Divide the ore into different particle size levels by adjusting the aperture size of the sieve. Laying the foundation for subsequent jig machine separation and fine-sorting operations.

2. Gravity beneficiation

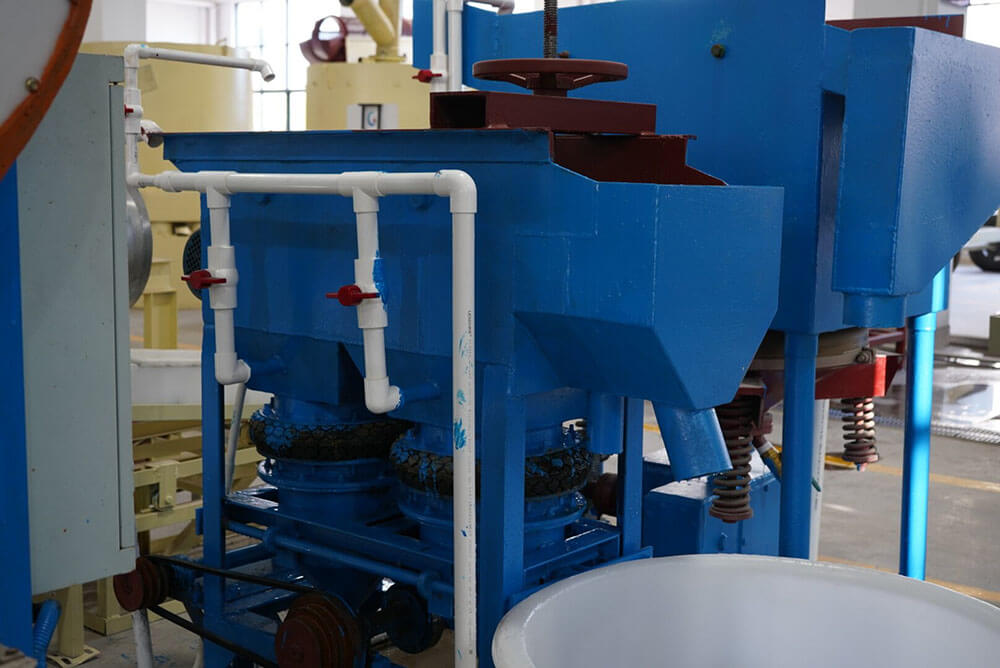

After primary classification, pour the ore into the jig separator for gravity separation. The jig separator is a traditional and highly efficient beneficiation equipment. It separates minerals of different densities by layering them in water through the water flow and mechanical vibration. The minerals of tantalum, niobium, tungsten, tin, and other metals have significant differences in density compared to waste rock, making jig separator an ideal choice for separating minerals.

3. Vibration Chute Separation

During the separation process, the vibration chute also plays an important role. It simulates the flow pattern of natural rivers and enhances the separation effect between mineral particles through its unique agitation effect. This method is particularly suitable for processing fine-grained ores and effectively improves the recovery rate of metals such as tungsten and tin.

4. Magnetic and electrical separation

Subsequently, the ore will undergo magnetic separation through three magnetic separators. The three-disc magnetic separator has a strong magnetic field strength and a wide sorting range, which can accurately separate minerals containing ferromagnetic substances. Magnetic separation is indispensable for non-ferromagnetic metals purification such as tantalum and niobium.

After magnetic separation, use the high-voltage electric separator for further selection work. High voltage electric separating machines rely on high-voltage electric fields to charge mineral particles and achieve sorting based on the differences in electrical conductivity of different minerals. This step is crucial for improving the purity of the final product, especially for separating minerals with significant differences in conductivity.

5. Comprehensive processing and purification

After the above steps, enrich metals such as tantalum, niobium, tungsten, and tin in the raw ore. It requires further purification processes such as chemical treatment to meet the requirements of industrial applications. This may include solvent extraction, ion exchange, and electrolysis to remove residual impurities and obtain high-purity metals.

Tungsten Tin Beneficiation Test

Tungsten tin ore has wide applications in aviation, aerospace, electronics, military, and other fields. The mining and processing of tungsten tin ore are of great significance for safeguarding national economic and defense security. Gravity beneficiation is an essential sorting method in the processing of tungsten tin ore. This article will introduce the operational steps and experimental results of the gravity beneficiation test for tungsten tin ore.

1. Purpose of the experiment

The purpose of this experiment is to separate tungsten tin ore through gravity beneficiation and obtain flotation concentrate and tailings of tungsten tin ore, providing a reference for subsequent processing.

2. Experimental principle

Gravity beneficiation is a method of sorting minerals by utilizing their different settling velocities in a gravity field. In tungsten tin ore, minerals with higher hardness(quartz and galena settle)sink faster than minerals with lower hardness(tungsten and tin). Therefore, valuable minerals such as tungsten and tin are separable from priceless minerals such as quartz and galena through gravity beneficiation.

3. Experimental steps

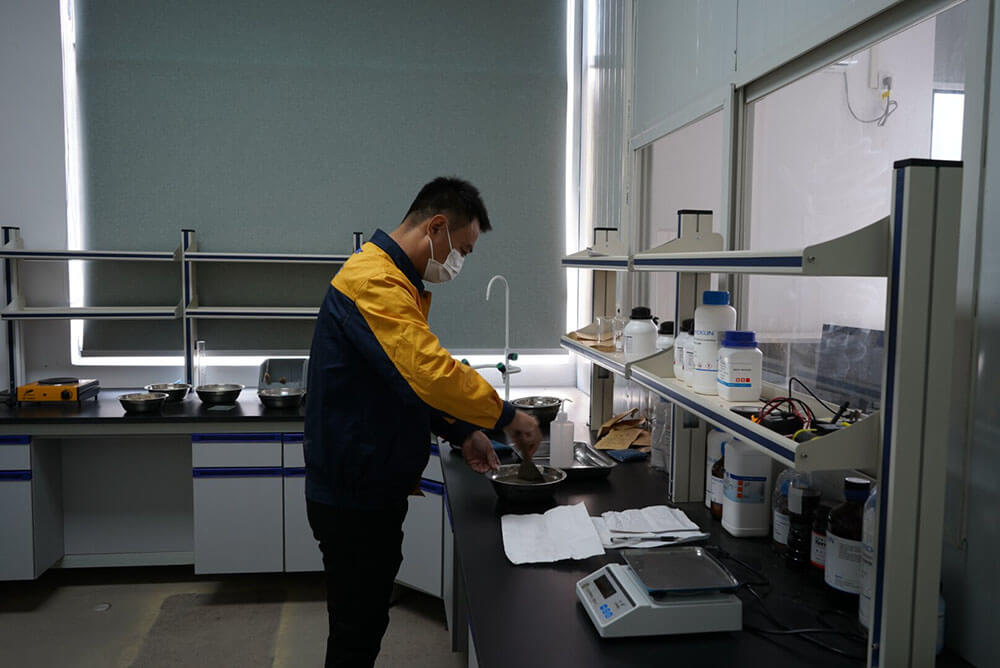

- Take a certain amount of tungsten tin ore sample, and after crushing, grinding, and other treatments, prepare a slurry with a particle size of -0.074mm.

- Pour the sample slurry into the gravity beneficiation equipment, turn on the equipment, and adjust the inclination angle, water flow rate, and other parameters to achieve the best sorting effect.

- After running the equipment for a certain time, stop the equipment and remove the flotation concentrate and tailings from the equipment for chemical analysis and physical property testing.

- Based on the experimental results, calculate the sorting rate, recovery rate, and other indicators of tungsten tin ore, and conclude data analysis and conclusion summary.

4. Precautions for tin ore gravity separation

- It should carry out strictly for sample preparation by regulations to ensure the accuracy of the test results.

- The professionals should carry out the inspection and adjust the test equipment to ensure the operation.

- Adjust the setting of the test conditions according to the actual situation to achieve the best test results.

- During the test operation, it is necessary to pay attention to the operation of the ore dressing machine and adjust the test conditions in time to obtain the best test results.

- Adjust the setting of experimental conditions according to the actual situation to achieve the best experimental effect.

- During the experimental operation, it is necessary to observe the operation of the ore dressing machine and adjust the experimental conditions promptly to achieve the best experimental results.

5. Analyzing the experimental results

In analyzing the experimental results process, it is necessary to analyze the experimental data to draw accurate conclusions.

The tin ore beneficiation test is an essential process, it can effectively improve the grade and recovery rate of tin ore. The experimental operation needs to strictly follow precautions to ensure the accuracy of the experimental results. Through tin ore beneficiation experiment, it improves the grade and recovery rate of tin ore, providing strong support for the tin ore mining extraction.

JXSC lab mineral processing equipment manufacturer has more than 38 years of experience in mining processing. We provide various lab mining equipment including gravity-separating equipment for processing minerals such as gold, tin, tungsten, lead, zinc, tantalum, niobium, iron, manganese, silver, titanium-iron, etc. Lab machines include laboratory jaw crusher, hammer crusher, roller crusher, grinding equipment, lab gravity separator, screening, washing equipment, etc. Welcome to consult!