what is it

Laboratory Hydrocyclone

Capacity: 0.05-25 m³/hr

Application: Widely used in solid-liquid separation of materials in industries such as mining, laboratory mineral processing, environmental testing, oil and gas, bioengineering and pharmaceutical research.

Description

The laboratory hydrocyclone is a classifying, thickening, desliming, and dewatering device that separates solid particles and liquids in a mixture. It is typically used for laboratory research, small-scale testing or small-scale production processes to separate particulate matter of different particle sizes, densities or shapes. With adjustable settings and customizable options, the JXSC laboratory hydrocyclone meets the diverse research needs of industries ranging from pharmaceuticals to wastewater treatment plants. The compact size, effective separation of solid particles from liquids and fast throughput capability have made this equipment popular in research laboratories worldwide.

Advantages

Small size

Thanks to their small footprint, they can be easily installed in any laboratory without taking up much space.

High-quality material

The lining is made of high wear-resistant rubber, which is light in weight, strong in wear resistance, and not easy to age and rust.

Adjustable

The laboratory hydrocyclone can realize the classification of different particle sizes by adjusting the feed flow rate, discharge port diameter and geometric parameters of the equipment.

Wide range of applications

Our laboratory hydrocyclones can process various suspended liquids, including solid particles, sediments, ores, ore pulp, etc.

Principle

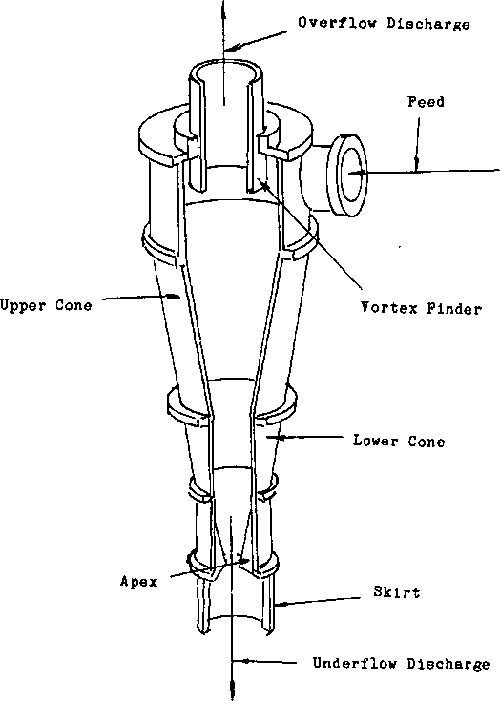

The working principle of the laboratory hydrocyclone is based on the centrifugal force generated during the rotation of the liquid, so that the particles are separated along the direction of the centrifugal force. The liquid mixture enters the cyclone through the feed port, and forms a high-speed rotating flow field in the cylinder. Due to the difference in density between the solid particles in the liquid and the liquid, the particles in the liquid will be subjected to centrifugal force, causing the heavy particles to move towards the outer wall of the equipment and finally be discharged at the bottom of the cylinder. Conversely, lighter materials move toward the center of the equipment and flow out from the top of the hydrocyclone through the overflow port.

Specification

| Model | FX10 | FX25 | FX50 | FX75 | FX100 |

| Interior Diameter (mm) | 10 | 25 | 50 | 75 | 100 |

| Feed Pressure (MPa) | 0.1-0.6 | 0.1-0.6 | 0.1-0.4 | 0.1-0.4 | 0.1-0.3 |

| Cone Angle (°) | 8 | 8 | 8 | 8 | 8 |

| Separation Size (μm) | 1-5 | 5-20 | 5-40 | 10-40 | 20-50 |

| Vortex Finder (mm) | – | 5,6,7 | 7.5,9,11 | 17 | 20, 30 |

| APEX (mm) | – | 1,2,3 | 2,3,4 | 4,5,6,8,10,12 | 14-30 |

| Capacity (m³/hr) | 0.05-0.1 | 0.3-1 | 2-5 | 5-10 | 6-25 |

| Weight (kg) | 0.5 | 1 | 2 | 4 | 8 |