what is it

Laboratory Jaw Crusher

Popular Models: The 911MPE-24, 911MPE-44, 911MPE-56 and 911MPE-6100 laboratory jaw crushers are ideal for crushing medium-hard ores and stones. The energy source can be electric motor or diesel engine.

Capacity: 45kg-10t/hr

Application: It is widely used in scientific research, laboratory and small-scale production in the fields of metallurgy, geology, chemical industry, building materials, etc., including studying the crushing characteristics of different materials, conducting sample preparation or preliminary crushing tests, and can also be used in teaching laboratories and training institutions.

Description

JXSC laboratory jaw crusher is a kind of equipment used to crush rocks, ores and other hard materials, mainly used to study the physical characteristics of samples, the mechanical properties of rocks and the crushing performance of ores. Researchers can simulate different crushing conditions by adjusting the parameters of the laboratory jaw crusher, such as jaw plate spacing and feed size, and analyze and evaluate the ore samples. It has the advantages of high efficiency, simple structure, low energy consumption and adaptability to multiple purposes. It can meet the crushing needs of small and medium-sized ore samples in various scientific research and laboratories.

Advantages

Wide adaptability

Suitable for materials of various hardness and brittleness, including rock, ore, slag, building materials, etc.

High-efficiency crushing capacity

The crusher feed port is large, which can handle larger raw materials and improve crushing efficiency.

Good particle size controllability

The crushing particle size can be controlled by adjusting the size of the crushing cavity and the angle of the jaw plate.

Simple operation & maintenance

Composed of upper and lower jaw plates, transmission devices and adjustment devices, this simple structure makes operation and maintenance relatively easy.

Low energy consumption & noise

The laboratory jaw crusher has low energy consumption and operating cost, and is very suitable for laboratories.

Reliable sample preparation tool

Lab jaw crushers are often used to prepare rock and ore samples before analysis, providing a reliable sample basis for scientific research.

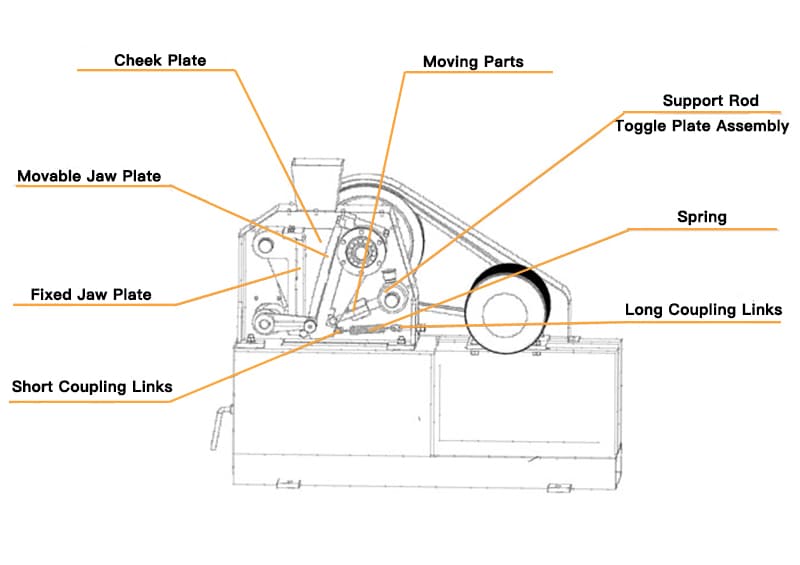

Principle

The lab jaw crusher comprises frame, motor, belt drive system, jaw plate and crushing cavity. There is a fixed jaw and a moving jaw, and a narrow crushing cavity is formed between the two jaws. The movable jaw plate is connected with the motion mechanism through the swing arm and can perform periodic reciprocating motion along the horizontal direction. The material is put into the crushing cavity through the feeding port and clamped by the movable and fixed jaw plates. When the movable jaw moves downward, the material is compressed and crushed. After that, when the movable jaw plate moves upwards, the crushed materials are discharged from the discharge port.

Specification

| Model | Feed Opening Size (mm) | Max. Feeding Size (mm) | Regulation Range of Discharge Opening (mm) | Capacity (kg/hr) | Main Shaft Speed (rpm) | Motor Power (kW) | Weight (kg) |

| PE100×60 | 100×60 | ≤50 | 1-6 | 45-550 | 600 | 2.2 | 186 |

| PE100×100 | 100×100 | ≤80 | 3-25 | 400-1800 | 500 | 3 | 300 |

| PE100×125 | 100×125 | ≤80 | 5-25 | 400-1800 | 500 | 3 | 320 |

| PE100×150 | 100×150 | ≤80 | 5-38 | 400-1800 | 500 | 3 | 360 |

| PE125×150 | 125×150 | ≤100 | 6-38 | 500-1800 | 500 | 3 | 1000 |

| PE150×250 | 150×250 | ≤125 | 10-40 | 1000-3000 | 350 | 7.5 | 1200 |

| PE200×300 | 200×300 | ≤165 | 20-70 | 2000-8000 | 265 | 7.5 | 800 |

| PE200×350 | 200×350 | ≤165 | 10-50 | 6t-10t | 308 | 7.5 | 1200 |