what is it

Single Flotation Cell

Capacity: 0.5-8L

cell vol: 0.2 -0.25mm

Application: XFD type single flotation machine is suitable for flotation testing of materials in laboratories or colleges and universities in geology, metallurgy, construction, chemistry, mining, coal and other industries.

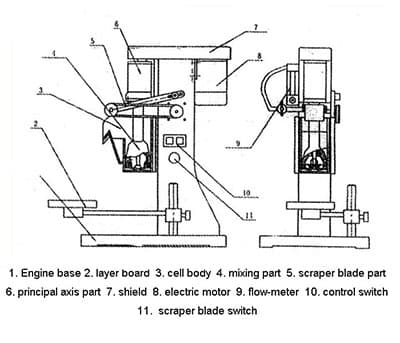

Description

The laboratory single flotation machine can flotation materials and is suitable for the separation of non-ferrous, ferrous metals and non-metals. The equipment has a simple structure and is easy to use. The impeller is made of stainless steel, which is corrosion-resistant and has a long service life. The speed of impeller and scraper can be adjusted to meet different flotation test requirements.

Advantages

The stirring tank has the functions of suction, slurry suction and flotation, forming a flotation circuit.

It is flexible to use, and the liquid level and inflation volume can be adjusted.

The built-in heater ensures the flotation working temperature and improves the efficiency (XFDⅢ~Ⅳ).

LCD digital display, impeller stepless speed regulation (XFDⅡ~Ⅳ).

Principle

The impeller of the single flotation machine in the laboratory rotates, and the negative pressure is formed by centrifugal action. On the one hand, air is sucked in, and on the other hand, the slurry is mixed with chemicals to form foam.

When in use, the ore sample mixed with water is first made into a slurry and then introduced into the tank, the motor is started, the main shaft rotates, the impeller starts to stir, and then the valve is opened to inflate. After adding the medicament, the foam gradually forms. After the scraped foam is processed, the ore sample after flotation can be obtained.

Specification

| Model | Cell Vol.(L) | Impeller Diameter (mm) | Impeller Speed (r/min) | Scraper Speed (r/min) | Feed Size (mm) | Motor Power (W) | Temperature Adjustment (℃) | Wight (kg) | Dimensions (mm L×W×H) | |||

| XFDⅠ | XFD-0.5 | 0.5 | Φ45 | 2416/2109 | 15/30 | <0.2 | 90 | / | 30 | 440 | 320 | 750 |

| XFD-0.75 | 0.75 | Φ45 | 2416/2109 | 30 | 440 | 320 | 750 | |||||

| XFD-1 | 1 | Φ55 | 1956/1726 | 35 | 440 | 320 | 840 | |||||

| XFD-1.5 | 1.5 | Φ60 | 1764/1572 | 40 | 440 | 320 | 840 | |||||

| XFD-3 | 3 | Φ70 | 1764/1572 | 50 | 440 | 320 | 890 | |||||

| XFD-8 | 8 | Φ80 | 1400 | 80 | 730 | 450 | 900 | |||||

| XFDII | XFDII-0.5 | 0.5 | Φ45 | 0-2800 | 15/30 | <0.25 | 120 | / | 30 | 420 | 320 | 750 |

| XFDII-0.75 | 0.75 | Φ45 | stepless | 30 | 440 | 320 | 750 | |||||

| XFDII-1 | 1 | Φ55 | 35 | 440 | 320 | 840 | ||||||

| XFDII-1.5 | 1.5 | Φ60 | 40 | 440 | 320 | 840 | ||||||

| XFDII-3 | 3 | Φ70 | 50 | 440 | 320 | 890 | ||||||

| XFDII-8 | 8 | Φ80 | 80 | 730 | 450 | 900 | ||||||

| XFDIII | XFDIII-0.5 | 0.5 | Φ45 | 0-2800 | 15/30 | <0.25 | 120 | 50-150 | 30 | 440 | 320 | 750 |

| XFDIII-0.75 | 0.75 | Φ45 | stepless | 30 | 440 | 320 | 750 | |||||

| XFDIII-1 | 1 | Φ55 | 35 | 440 | 320 | 840 | ||||||

| XFDIII-1.5 | 1.5 | Φ60 | 40 | 440 | 320 | 840 | ||||||

| XFDIII-3 | 3 | Φ70 | 50 | 440 | 320 | 890 | ||||||

| XFDIII-8 | 8 | Φ80 | 80 | 730 | 450 | 900 | ||||||

| XFDⅣ | XFDⅣ-0.5 | 0.5 | Φ45 | 0-2800 | 0-30 (stepless regulation) | <0.2 | 120 | optional | 30 | 620 | 300 | 825 |

| XFDⅣ-0.75 | 0.75 | Φ45 | stepless | |||||||||

| XFDⅣ-1 | 1 | Φ55 | ||||||||||

| XFDⅣ-1.5 | 1.5 | Φ60 | ||||||||||

| XFDⅣ-3 | 3 | Φ70 | ||||||||||