what is it

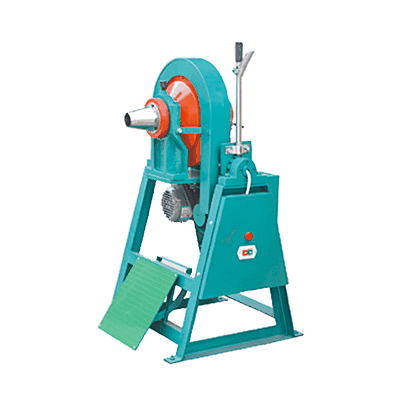

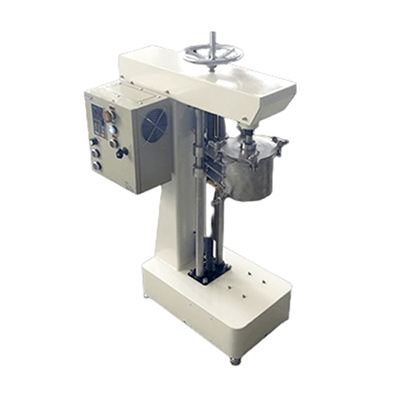

Jar Mill

Popular Models: The 911MPEBR500 can evenly mix and finely grind samples.

Volume: 0.5-30L

Application: Laboratory Jar Mill is widely used in various laboratory research, such as material research, chemical experiment, drug development, etc. It can grind and mix materials of different particle sizes and properties to achieve fine grinding and uniform mixing of samples.

Description

The Laboratory Jar Mill is a laboratory grinding device used for grinding and mixing various substances. It can be ground dry or wet and consists of a grinding jar and a fixed grinding rod. Grinding jars are usually made of wear-resistant materials such as ceramic, glass or stainless steel and can hold samples of varying volumes.

There are single-tier and multi-tier types, with one deck holding four jars. The maximum capacity is 20L.

(1) Grinding jar material type: nylon, corundum/alumina, stainless steel, polyurethane and other special materials;

(2) Ball material type: stainless steel balls, aluminum balls/corundum balls, agate balls, zirconia balls, hard alloy balls, etc.

We can customize products according to your needs, welcome to consult!

Advantages

It can be used in single or multiple grooves, and can grind a variety of samples at the same time.

The grinding rotation speed and grinding time can be adjusted according to the needs to meet different experimental requirements.

The distance between the rollers can be adjusted to adapt to different sizes of grinding jars.

Equipped with grinding jars and grinding media of different specifications, it can grind a wide variety of materials.

Principle

The motor drives the shaft and roller to rotate, driving the grinding jar to roll, so that friction and impact force are generated between the abrasive and the sample, and the grinding and mixing of the sample is realized. During the rotation process of the abrasive in the tank, it is constantly in contact with the material, so that the sample is gradually ground into the required particle size.

Specification

| Model | Adaptive Jar | Tiers | Roller shafts | Available jar diameter(mm) | RPM | Voltage | Working power | Dimensions | Transmission mode | ||||

| Volume | Quantity | Quantity (per tier) | Diameter | Length | Adjustable spacing | (V) | (KW) | (L*W*H/ mm) | |||||

| GMS1-2 | 0.5-1L | 2 | 1 | 2 | φ40 | 180 | 52~160 | φ50-φ160 | 0~300 | 220V | 0.75 | 580*420*410 | Belt |

| GMS3-2 | 0.5-3L | 2 | 1 | 2 | φ50 | 220 | 52~210 | φ50-φ200 | 0~300 | 220V | 0.75 | 660*440*410 | Belt |

| GMS5-1 | 0.5-5L | 1 | 1 | 2 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 0.75 | 500*350*320 | Belt |

| GMS5-2 | 0.5-5L | 2 | 1 | 2 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 0.75 | 760*610*530 | Belt |

| GMS10-2 | 0.5-10L | 2 | 1 | 2 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 220V | 1.5 | 790*630*530 | Synchronous belt |

| GMS20-2 | 0.5-20L | 2 | 1 | 2 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 2.2 | 827*952*724 | Synchronous belt |

| GMS30-2 | 1-30L | 2 | 1 | 2 | φ80 | 425 | 35~290 | φ60-φ360 | 0~200 | 380V | 2.2 | 1328*658*720 | Synchronous belt |

| GMS1-4 | 0.5-1L | 4 | 1 | 3 | φ40 | 180 | 62~160 | φ50-φ160 | 0~300 | 220V | 0.75 | 580*520*410 | Belt |

| GMS3-4 | 0.5-3L | 4 | 1 | 3 | φ50 | 230 | 76~230 | φ70-φ180 | 0~270 | 220V | 0.75 | 780*648*530 | Belt |

| GMS5-4 | 0.5-5L | 4 | 1 | 3 | φ60 | 390 | 67~280 | φ70-φ260 | 0~270 | 220V | 1.5 | 850*748*530 | Belt |

| GMS10-4 | 0.5-10L | 4 | 1 | 3 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 380V | 2.2 | 1189*890*680 | Synchronous belt |

| GMS10-4B | 0.5-10L | 4 | 2 | 2 | φ70 | 390 | 67~230 | φ60-φ280 | 0~220 | 380V | 2.2 | 742*890*1111 | Synchronous belt |

| GMS20-4 | 0.5-20L | 4 | 2 | 3 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 2.2 | 1309*1128*724 | Chain wheel |

| GMS30-4 | 1-30L | 4 | 1 | 3 | φ80 | 425 | 35~290 | φ60-φ360 | 0~200 | 380V | 4 | 1328*1048*680 | Synchronous belt |

| GMS3-8 | 0.5-3L | 8 | 2 | 3 | φ50 | 230 | 76~230 | φ70-φ200 | 0-280 | 380V | 1.1 | 780*717*965 | Belt |

| GMS5-8 | 0.5-5L | 8 | 2 | 3 | φ60 | 310 | 67~280 | φ70-φ260 | 0-270 | 380V | 2.2 | 1020*868*950 | Chain wheel |

| GMS10-8 | 0.5-10L | 8 | 2 | 4 | φ70 | 410 | 67~302 | φ60-φ280 | 0~220 | 380V | 3 | 1210*890*1050 | Chain wheel |

| GMS20-8 | 0.5-20L | 8 | 2 | 4 | φ80 | 470 | 30~340 | φ60-φ320 | 0~220 | 380V | 3 | 1390*1128*1100 | Chain wheel |