what is it

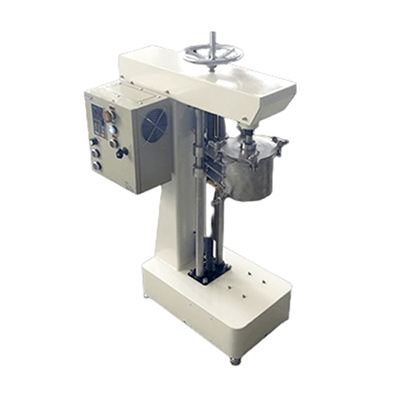

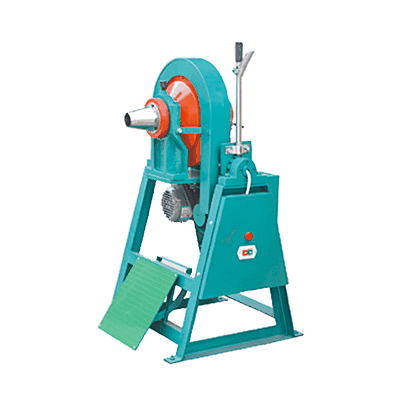

Laboratory Cone Ball Mill

Capacity: 200 -4000g/hr

Application: It is often used in the optional research of ore in schools and scientific research institutions, and it is also suitable for metallurgy, geology, chemical industry, building materials, coal and other fields.

Description

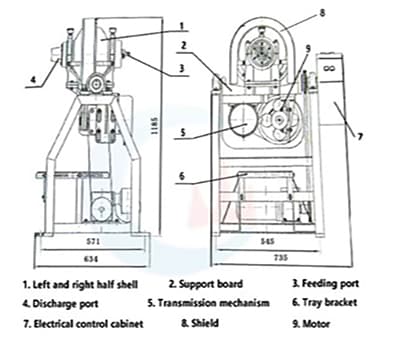

The lab cone ball mill can be ground dry or wet. Grinding ball material can be selected. It is composed of feeding, discharging, conveying, transmission and other parts. There is a wear-resistant liner inside the tube, and the hollow shaft is made of cast steel, and the liner can be replaced.

Advantages

The degree of automation is high, and the grinding time can be set.

Grinding evenly, preventing over-grinding, high-quality finished products.

Small size, light weight, easy installation.

Principle

There are large grinding balls and small grinding balls in the laboratory conical ball mill. The large grinding balls are located in the large diameter part of the cylinder, and the small grinding balls are located in the conical part. Coarse materials are coarsely crushed under the action of large grinding balls, then gradually move to the discharge port, and are finely ground by small grinding balls to finally achieve the desired grinding effect.

Specification

| Model | XMQ150×50 | XMQ150×100 | XMQ240×90 | XMQ350×160 |

| Drum Size (mm) | Φ150×50 | Φ150×100 | Φ240×90 | Φ350×160 |

| Capacity (g) | 200 | 400 | 1000 | 4000 |

| Feeding Size (mm) | ≤3 | ≤3 | ≤3 | ≤3 |

| Discharging Size (mm) | ≤0.074 | ≤0.074 | ≤0.074 | ≤0.074 |

| Power (kW) | 0.25 | 0.25 | 0.55 | 1.1 |

| Dimensions (mm) | 915×530×1160 | 915×750×1160 | 1050×640×1160 | 700×575×1190 |

| Weight (kg) | 90 | 130 | 170 | 300 |