what is it

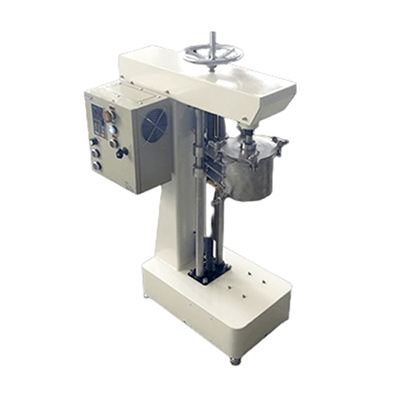

Planetary Ball Mill

Popular Models: The 911MPEPB500 Planetary Ball Mills are capable of finely grinding materials that are soft, hard to brittle, or fibrous. Both dry and wet grinding options are available.

Quantity: 2-4 adaptive Jars

Application: Planetary ball mill products are used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemicals, light industry, medicine, beauty and other industries.

Description

Planetary ball mills are often used for product mixing, fine grinding, small sample preparation, and nanomaterial dispersion. The equipment is small in size and high in efficiency. With four ball mill jars, four samples can be obtained at one time. There are various grinding methods, including dry grinding, wet grinding, vacuum grinding, and inert gas grinding. It is the best choice for laboratories to obtain microparticle samples.

Advantages

Small size, light weight, low noise.

It can be used for dry grinding, wet grinding, vacuum grinding and inert gas grinding.

Stepless speed regulation and timing operation are available.

The running direction can be one-way running, forward and reverse running.

The belt is adjustable in tightness and has a long service life.

Multiple samples can be ground at one time.

Principle

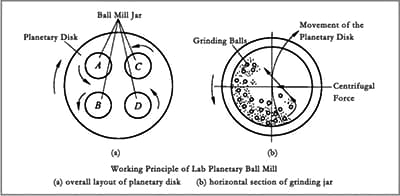

The planetary ball mill has four ball milling jars on the turntable. When the turntable rotates, the ball mill jars revolve around the axis of the turntable and rotate around their own axis to perform planetary motion. Grinding balls in the jar collide with each other at high speed, thereby grinding and mixing the sample. It can grind a variety of products, and the minimum particle size can reach 0.1 micron.

Specification

| Model | Volume (L) | Adaptive Jar | Adaptive Vacuum Jar (ml) | Working Voltage | Work Mode | Grinding Range | |

| Volume (ml) | Quantity | ||||||

| YXQM-0.4L | 0.4 | 50-100 | 2-4 | 50 | 220V 50HZ | 2 or 4 jars working simultaneously | Dry/Wet Milling |

| YXQM-1L | 1 | 50-250 | 50-100 | 220V 50HZ | |||

| YXQM-2L | 2 | 50-500 | 50-250 | 220V 50HZ | |||

| YXQM-4L | 4 | 50-1L | 100-500 | 220V 50HZ | |||

| YXQM-8L | 8 | 500-2L | 250-1000 | 220V 50HZ | |||

| YXQM-10L | 10 | 500-2.5L | 250-2.5L | 380V 50HZ | |||

| YXQM-12L | 12 | 1L-3L | 500-3L | 380V 50HZ | |||

| YXQM-16L | 16 | 1L-4L | 500-4L | 380V 50HZ | |||

| YXQM-20L | 20 | 1L-5L | 1000-5L | 380V 50HZ | |||

| YXQM-40L | 40 | 4L-10L | 3000-10L | 380V 50HZ | |||

| YXQM-60L | 60 | 6L-15L | 5000-15L | 380V 50HZ | |||

| YXQM-80L | 80 | 6L-20L | 5000-20L | 380V 50HZ | |||

| YXQM-100L | 100 | 10L-25L | 9000-25L | 380V 50HZ | |||

| YXQM-120L | 120 | 10L-30L | 9000-30L | 380V 50HZ | |||

| YXQM-160L | 160 | 10L-40L | 9000-40L | 380V 50HZ | |||

| Model | Speed Frequency | Transmission mode | Rotation speed (r/min adjustable) | Revolution speed (r/min adjustable) | Material Capacity | Input Granularity Size | Output Granularity Size |

| YXQM-0.4L | Adjustable | Gear drive | 10-900 | 5-450 | Material +Mill balls < 2/3 volume | < 10 mm for soft material, < 3 mm for hard material | < 75um-0.1um(100nm) |

| YXQM-1L | 10-900 | 5-450 | |||||

| YXQM-2L | 10-800 | 5-400 | |||||

| YXQM-4L | 10-800 | 5-400 | |||||

| YXQM-8L | 10-640 | 5-320 | |||||

| YXQM-10L | 10-640 | 5-320 | |||||

| YXQM-12L | 10-640 | 5-320 | |||||

| YXQM-16L | 10-560 | 5-280 | |||||

| YXQM-20L | 10-460 | 5-230 | |||||

| YXQM-40L | 10-440 | 5-220 | |||||

| YXQM-60L | 10-360 | 5-180 | |||||

| YXQM-80L | 10-360 | 5-180 | |||||

| YXQM-100L | 10-360 | 5-180 | |||||

| YXQM-120L | 10-360 | 5-180 | |||||

| YXQM-160L | 10-320 | 5-160 | |||||