what is it

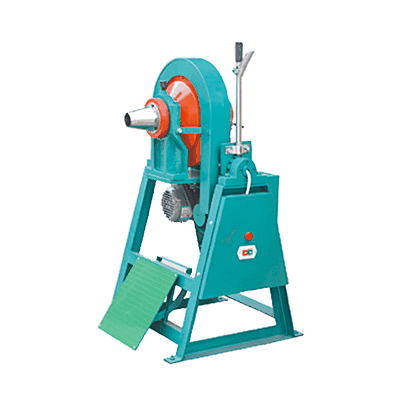

QM Cylinder Ball Mill

Popular Models: The 911MPELMBM-150/300 is suitable for dry grinding, with large capacity and high working efficiency.

Capacity: 45-350 kg/hr

Application: It is suitable for laboratories of building materials, metallurgy, coal, chemical industry, agriculture and ceramics or other small industrial grinding materials.

Description

The laboratory cylinder grinder is an important equipment for material crushing. It has a large processing capacity, a wide range of uses, and many types of materials that can be ground. The material of the grinding cylinder can be carbon steel or stainless steel, and the stainless steel material can prevent iron from polluting the material. The equipment has two types: batch type and continuous type, both of which can be used for dry grinding or wet grinding.

Advantages

Compact structure, small footprint.

The cylinder is integrally formed.

Copper core motor, long service life.

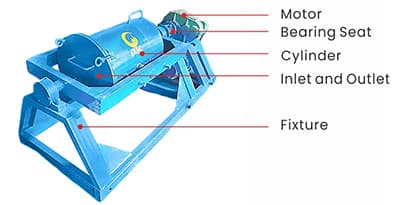

Principle

The grinding material enters the grinding cylinder through the feeding port, rotates with the grinding ball together with the grinding cylinder, and collides inside the cylinder, thereby being crushed and finely ground. The particle size of the ore is generally less than 30mm, and it can grind 15-30kg of material at a time. Steel balls can be replaced with steel rods as needed, and used as a rod mill.

Specification

| Model | MQ480*600 | MQ460*600 | MQ420*600 | MQ300*500 |

| Volume(L) | 110 | 100 | 92 | 65 |

| Speed( r/min) | 43 | 48 | 56 | 62 |

| Feed Size(mm) | 2-25 | 2-20 | ||

| Maximum Feeding Amount (kg/time) | 60 | 50 | 40 | 30 |

| Capacity(kg/h) | 45-350 | 5-200 | 40-150 | 30-100 |

| Discharge Size(mesh) | 200 | |||

| Balls(kg) | 180 | 138 | 86 | 53 |

| Motor(kw) | 2.2 | 1.5 | 1.1 | 1.1 |

| Over Size(mm) | 1650*900*1050 | 1600*850*1000 | 1490*790*900 | 1180*780*760 |